Compensating pipe seal

The compensating attachable duct collars from Hauff-Technik are the universal two-in-one solution for subsequent installation via core drill holes and small break-throughs, in which the seal is already integrated on the media line being fed in.

Compensating pipe seal

Sealing Sleeves for Core Drills and Wall Penetrations

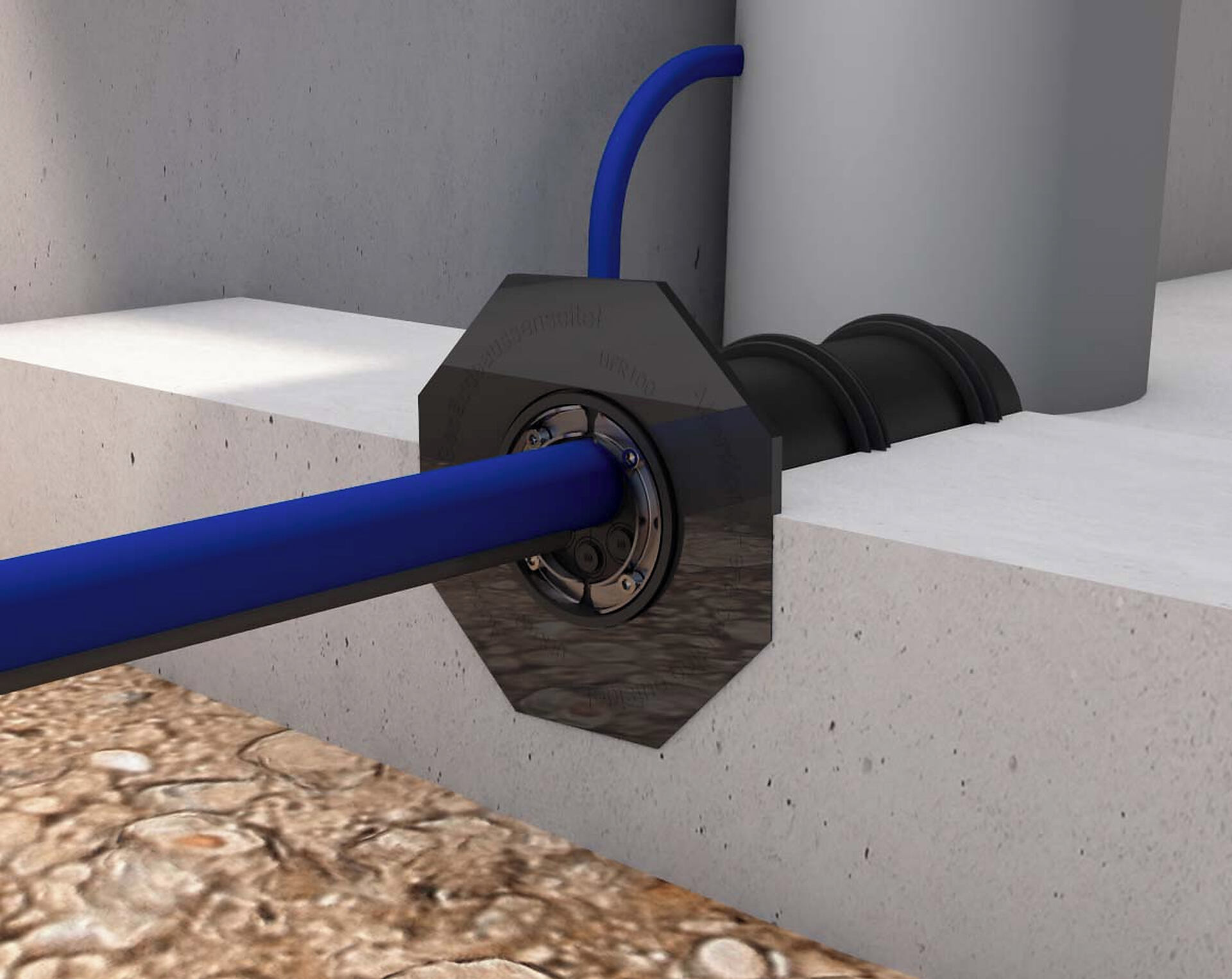

When retrofitting supply lines into buildings, it’s common to utilize core drilling or simple wall penetrations. While these solutions are quick to implement, they often present challenges when it comes to sealing. Hauff-Technik provides sealing sleeves designed specifically for these situations, offering an effective solution for reliable sealing. These sealing sleeves are engineered to ensure that utility lines are securely sealed, preventing the ingress of water and gas. With an easy installation process, they can be quickly mounted on existing core drills or wall openings, ensuring a professional finish. Hauff-Technik’s sealing sleeves are an excellent choice for maintaining the structural integrity of your building while effectively managing the entry of essential utilities.

Functionality and Installation of Hauff-Technik Sealing Sleeves

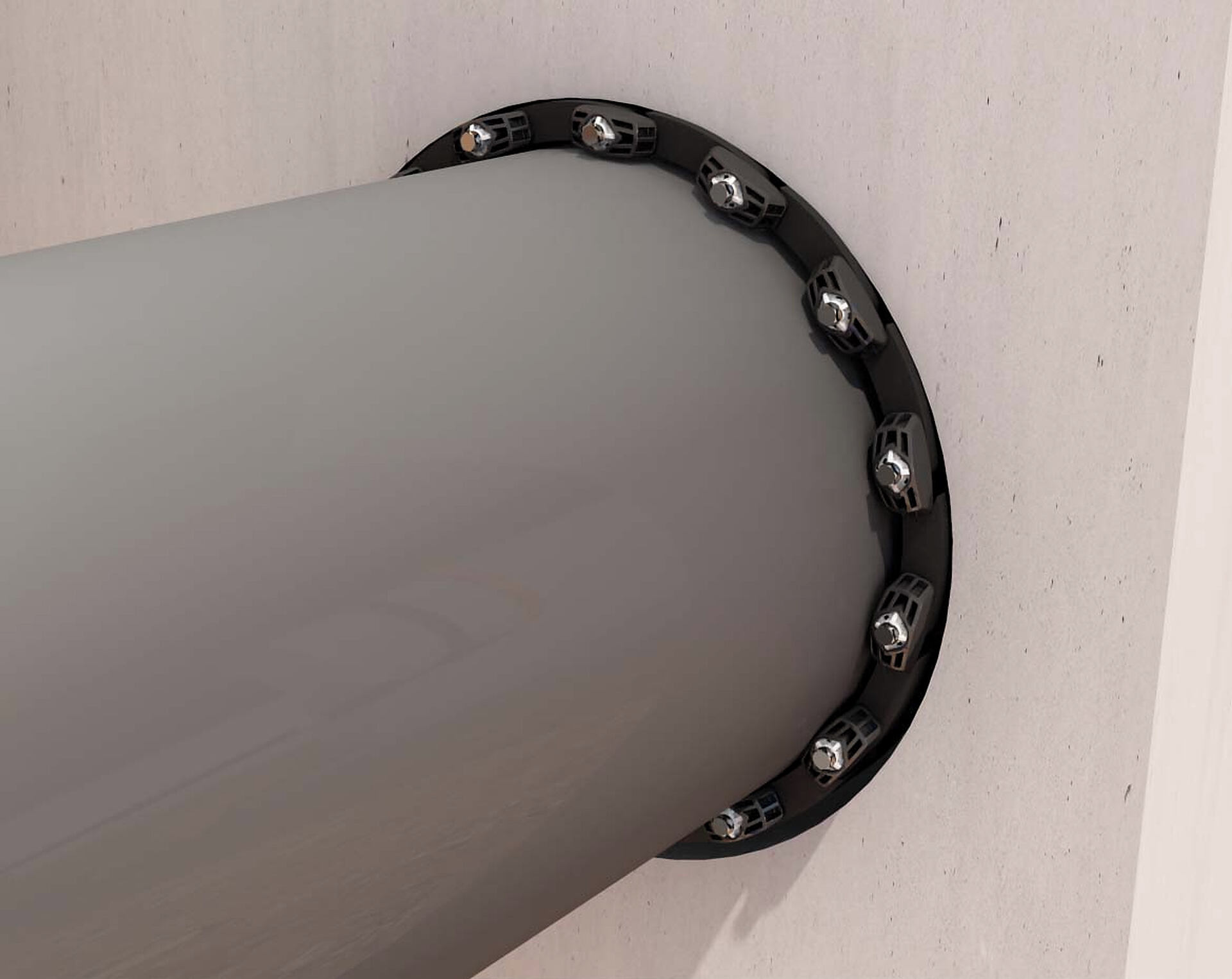

Hauff-Technik sealing sleeves are designed for direct mounting on walls and are commonly used for creating horizontal house entries. The supply line can be introduced through a liner pipe, a core bore, a metal housing, or a wall penetration. During installation, the first step is to determine the necessary diameter for the wall penetration. The fastening element is then coated with Hauff-Technik’s EGO sealing compound, which is available as an accessory.

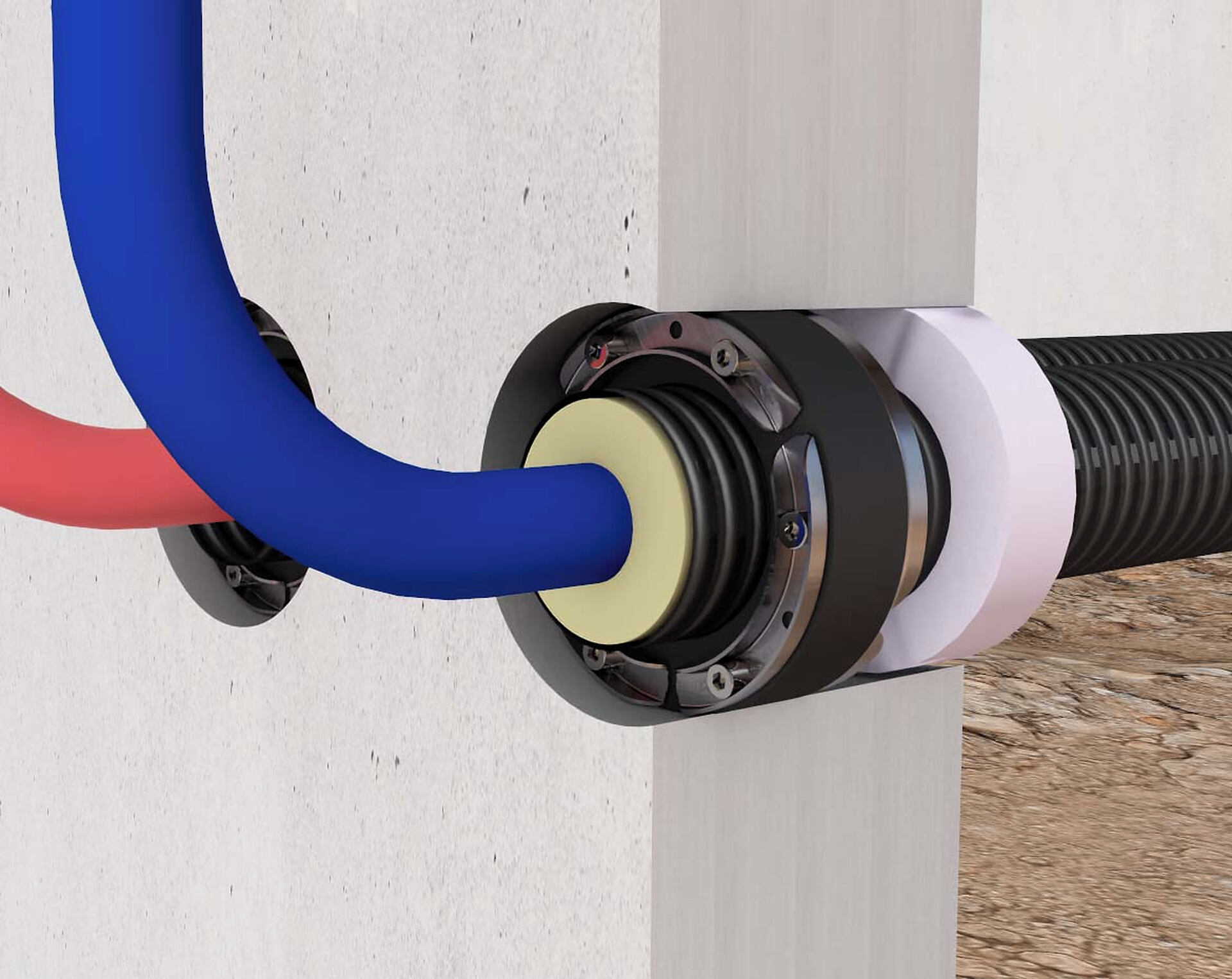

Next, the sealing sleeve is secured to the wall using screws. The media pipe is passed through the sleeve, which features segment rings on the inside. This design allows for precise adjustment of the entry diameter to fit the specific media line. Finally, sealing between the media line and the sealing sleeve is achieved with a tension band, which can be quickly and accurately tightened using a ratchet.

Hauff-Technik Sealing Sleeves in Various Designs

Hauff-Technik offers compensating attachable duct collars in two different variants, each designed for specific applications. These sealing sleeves cater to liner pipes and core boreholes with diameters of 150 mm and 200 mm. The 150 mm sealing sleeve is suitable for media pipes with diameters of 75, 90, and 110 mm. In contrast, the larger sleeve can be used for sealing media pipes with diameters of 90, 110, 125, 140, and 160 mm.

Both variants are wall sealing sleeves. These sealing sleeves meet the sealing standards according to DIN 18533 W1.1-E, DIN 18533 W1.2-E, and DIN 18533 W2.1-E. Therefore, installation is possible in virtually all situations, including walls affected by normal soil moisture and areas where standing or groundwater applies external pressure exceeding three meters.

Advantages of the Compensating Attachable Duct Collar

The main advantage of these sealing sleeves for pipes and conduits is the flexible connection they provide for core boreholes, openings, and recesses. The segment ring technology allows for an easy on-site adjustment of the appropriate diameter for the media line. The individual segments of the sleeve can accommodate three to five different diameters. Fine-tuning is achieved through robust stainless steel tension bands, which ensure strength and durability.

Hauff-Technik’s sealing sleeves create a tight seal not only for the media line but also for the wall penetration. This allows for the sealing of both areas in a single operation, saving time during the installation process. Additionally, the segment rings provide extreme adaptability, allowing the sleeve to conform to the diameter of the specific media line.

Another advantage is that these sealing sleeves are compatible with virtually all types of walls. The concrete must meet load classes 1 or 2, but the wall thickness is not a concern during installation. Thus, the sealing sleeve is suitable for both very thick walls and thin partitions. Moreover, this Hauff-Technik sleeve is suitable for nearly all situations, including areas at risk of flooding.

Installation is straightforward and does not require any special tools. A standard drill is needed to create the boreholes, and the tension bands and screws can be tightened using a ratchet. The only additional tool required is a hand press gun for the sealing compound.

Help us improve our website service.

Where would you place yourself?

Professional area

Architect & designer

Wholesaler

Telecoms

Utility company

Installer

Construction company

Private sector

Client

Applicant

Please choose your region

-

Belgium

Belgium

-

Česko

Česko

-

Danmark

Danmark

-

Deutschland

Deutschland

-

España

España

-

France

France

-

Global

Global

-

Hrvatska

Hrvatska

-

Italia

Italia

-

Luxembourg

Luxembourg

-

Magyarország

Magyarország

-

Nederland

Nederland

-

Österreich

Österreich

-

Polska

Polska

-

Schweiz

Schweiz

-

Slovenija

Slovenija

-

Slovensko

Slovensko

-

Sverige

Sverige

-

United Kingdom

United Kingdom

-

Global

Global

-

USA

USA

-

Global

Global

-

India

India

-

中国

中国

-

Global

Global

-

الإمارات العربية المتحدة

الإمارات العربية المتحدة