Sand sealant

The perfect refurbishment solution for subsequent sealing of substations.

Sand sealant

Hauff-Technik Sand Sealant – The Quick and Practical Solution for Sealing

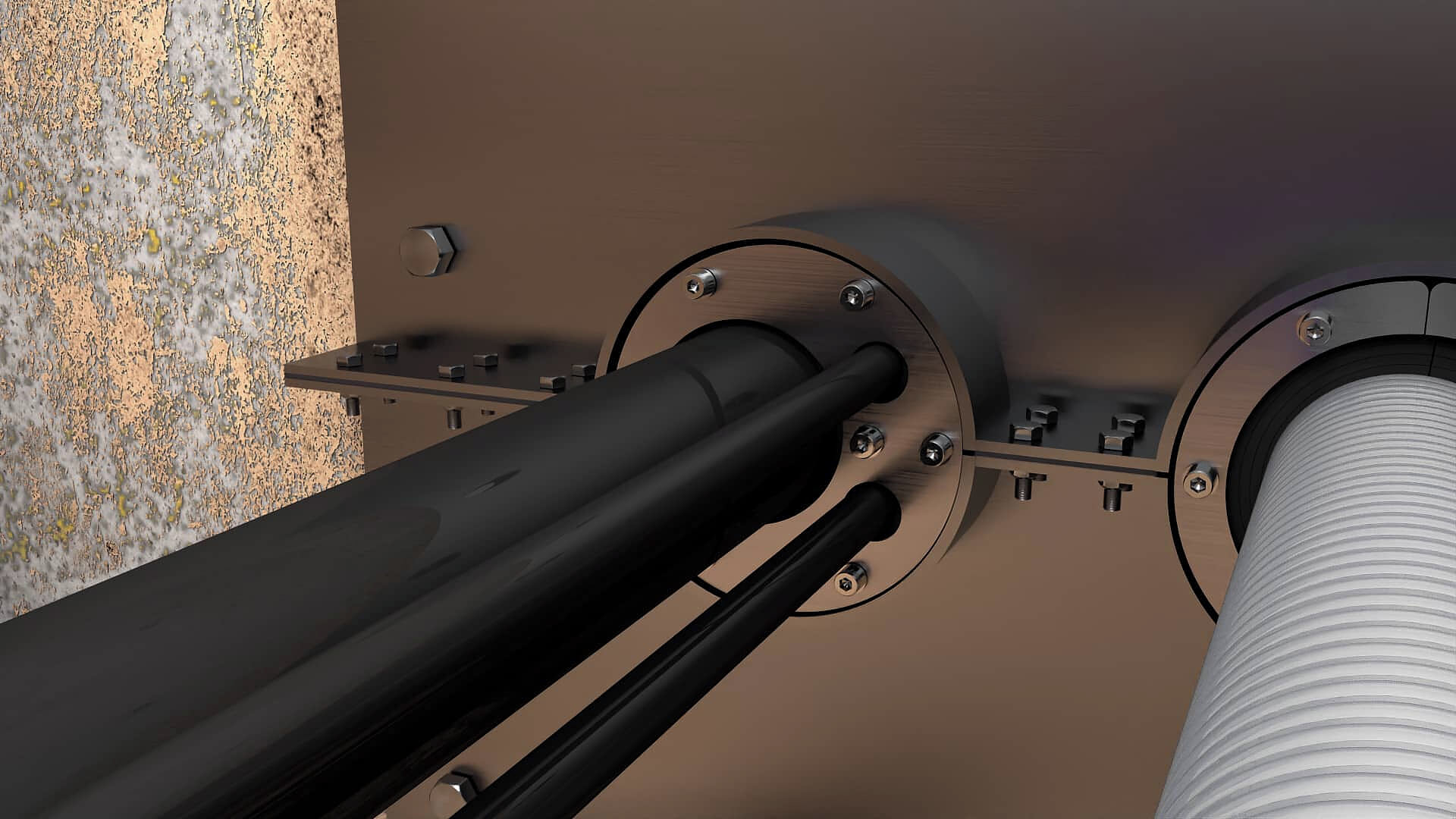

In transformer stations, soil moisture often poses significant challenges, particularly when cables are exposed as they enter the ground. Hauff-Technik sand sealant provides a practical and cost-effective solution specifically designed for this issue. It effectively mitigates the problem of water ingress, which can lead to damage to technical equipment. Such damage may cause failures in the local network and result in expensive repairs. In the worst-case scenario, entire transformers or switchgear may need to be replaced due to water damage.

Hauff-Technik Sealing Sand DiSan in Detail

Hauff-Technik sealing sand is a flowable, mineral-based sealing solution made from a mix of different sands and bentonite. This sand sealant boasts an exceptionally fine, optimized grain size of 0/2 mm. It is conveniently packaged in 20-kilogram bags, simplifying handling and transport.

Hauff-Technik Sand Sealant in Practical Use

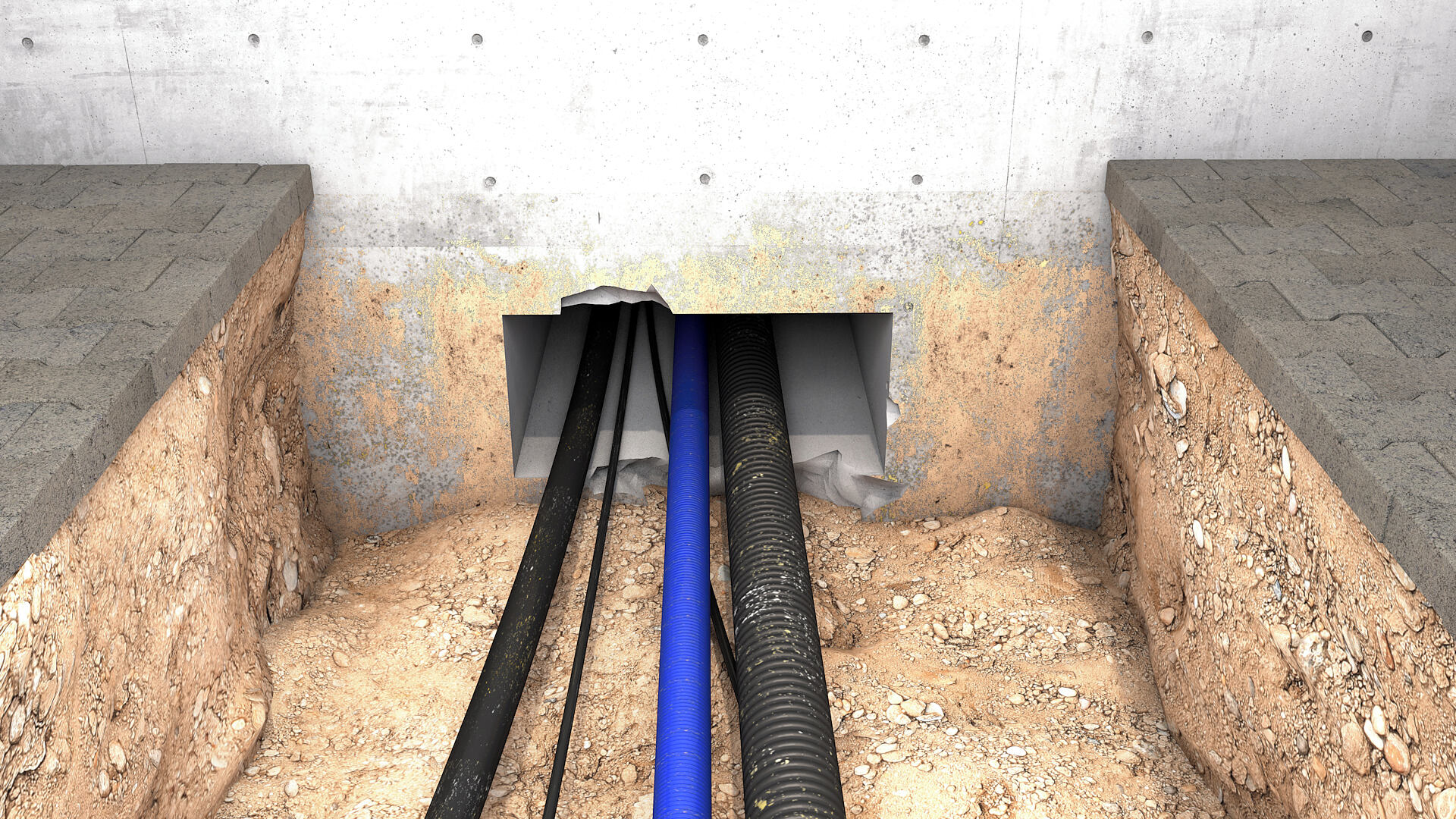

Local network and transformer station floors are often designed in an open manner, allowing numerous cables to enter the ground directly without barriers. These cables then extend to homes, other distribution stations, and main lines. The use of traditional entry systems and standard seals from building services is not feasible due to the high volume of cables, and the stations typically lack a foundation for embedding.

This configuration leads to significant challenges, as moisture can easily penetrate through the exposed soil. Extreme weather events frequently result in water seeping into the stations, particularly at the points where cables transition to the ground, which have proven to be weak spots. In many instances, heavy rainfall alone is sufficient to flood the distribution stations, causing severe damage and incurring substantial costs for operators.

Hauff-Technik sealing sand provides an elegant solution to this issue by reliably sealing these vulnerable areas. When in contact with water, the sand transforms into a hard, impermeable sealing mass. Its application is straightforward, requiring no preparation of the ground, and it is unaffected by the size of the area or the number of cables exiting the station. The sand can be easily poured over the exposed area and around existing cables, without necessitating complex post-processing. Only compaction with a tamper or hand tamper is needed, enabling the sealing mass to be applied quickly and nearly tool-free.

These attributes make Hauff-Technik sand sealant an ideal solution for sealing transformer stations, especially in scenarios where other sealing elements are not suitable. Additionally, it serves as an effective and economical renovation solution in areas where rising moisture has posed problems. To create a reliable and long-lasting sealing element, a minimum layer thickness of 30 cm is recommended. For conditions with high water pressure, using a greater quantity of sealing sand can enhance its effectiveness.

The required thickness of the layer depends on the anticipated water column. For a maximum water column of 100 cm, a minimum filling height of 80 cm of Hauff-Technik sand sealant is necessary. A sand sealant height of 140 cm can effectively contain a water column of up to 200 cm. DiSan from Hauff-Technik effectively prevents moisture infiltration during both summer and winter frost. The sand sealant has already demonstrated its suitability in practical applications within distribution stations.

Help us improve our website service.

Where would you place yourself?

Professional area

Architect & designer

Wholesaler

Telecoms

Utility company

Installer

Construction company

Private sector

Client

Applicant

Please choose your region

-

Belgium

Belgium

-

Česko

Česko

-

Danmark

Danmark

-

Deutschland

Deutschland

-

España

España

-

France

France

-

Global

Global

-

Hrvatska

Hrvatska

-

Italia

Italia

-

Luxembourg

Luxembourg

-

Magyarország

Magyarország

-

Nederland

Nederland

-

Österreich

Österreich

-

Polska

Polska

-

Schweiz

Schweiz

-

Slovenija

Slovenija

-

Slovensko

Slovensko

-

Sverige

Sverige

-

United Kingdom

United Kingdom

-

Global

Global

-

USA

USA

-

Global

Global

-

India

India

-

中国

中国

-

Global

Global

-

الإمارات العربية المتحدة

الإمارات العربية المتحدة